Alucobond

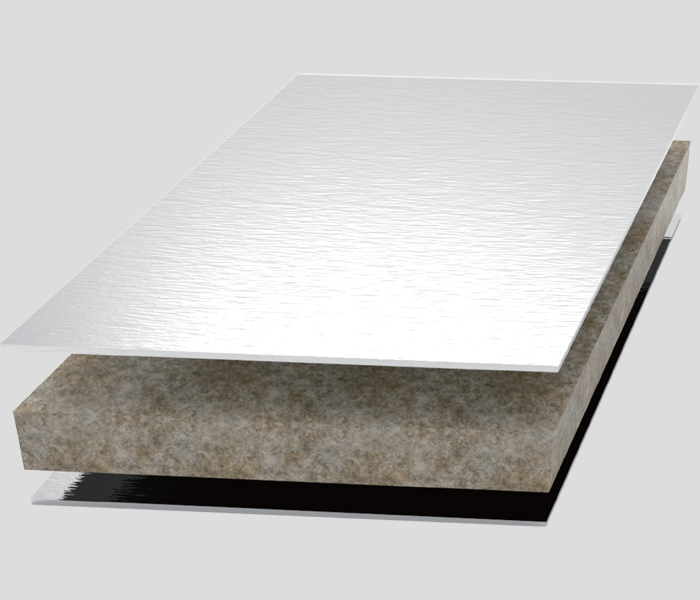

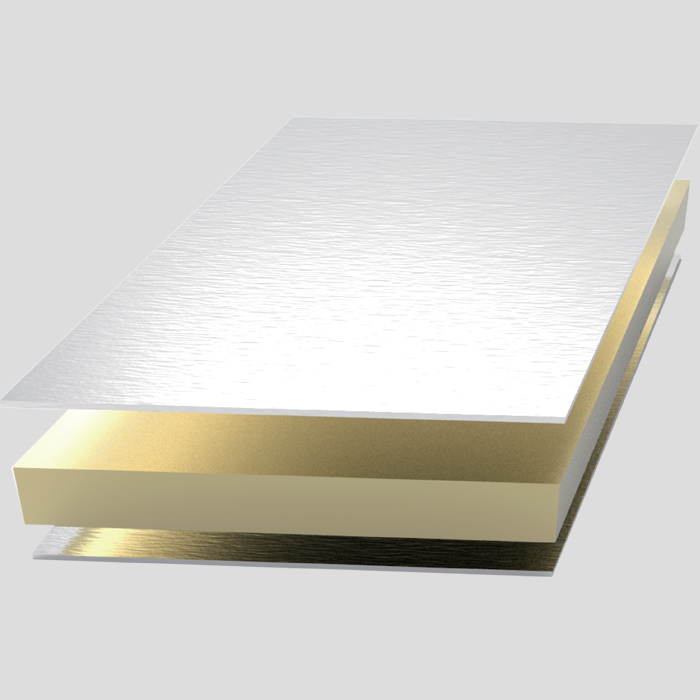

Alucobond A2

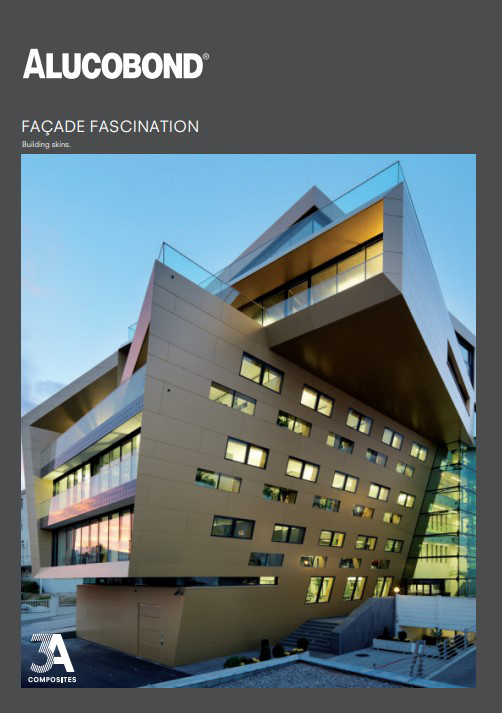

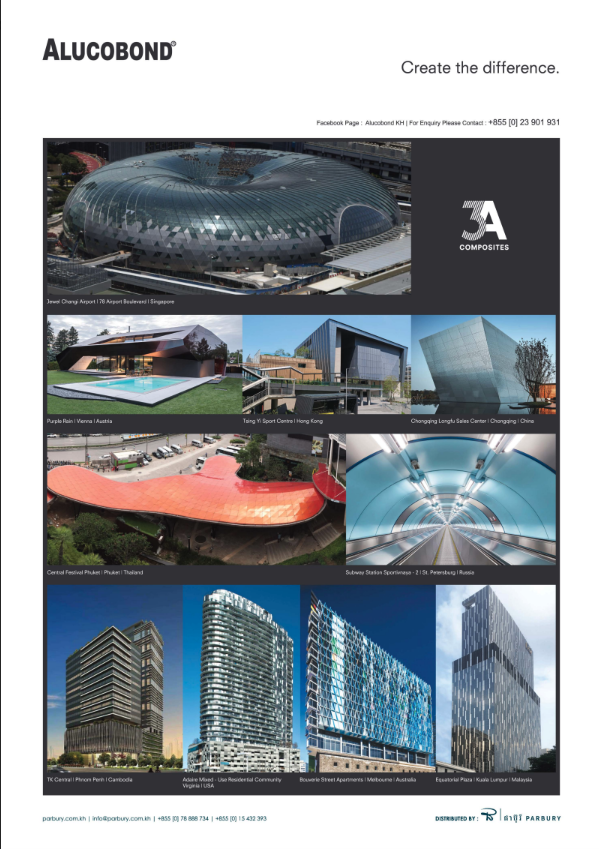

Across the world, Alucobond A2 is the only non-combustible aluminum composite panel used in architecture.

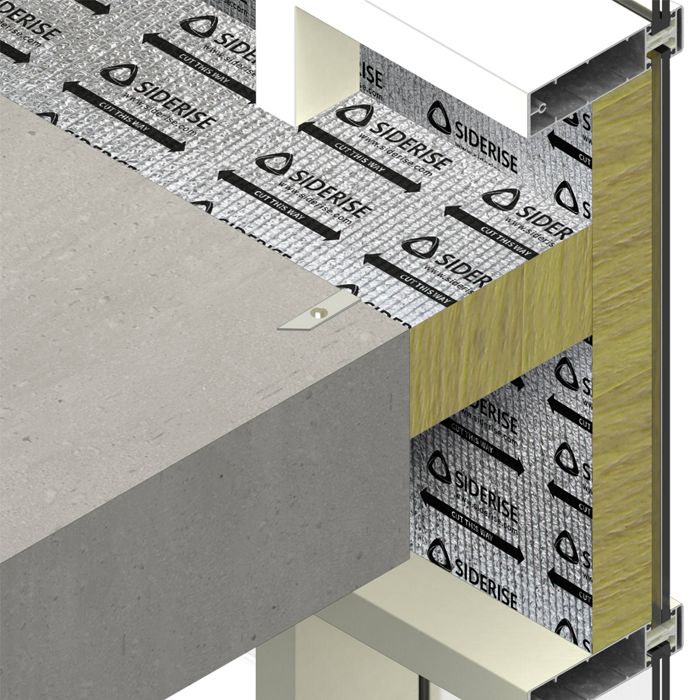

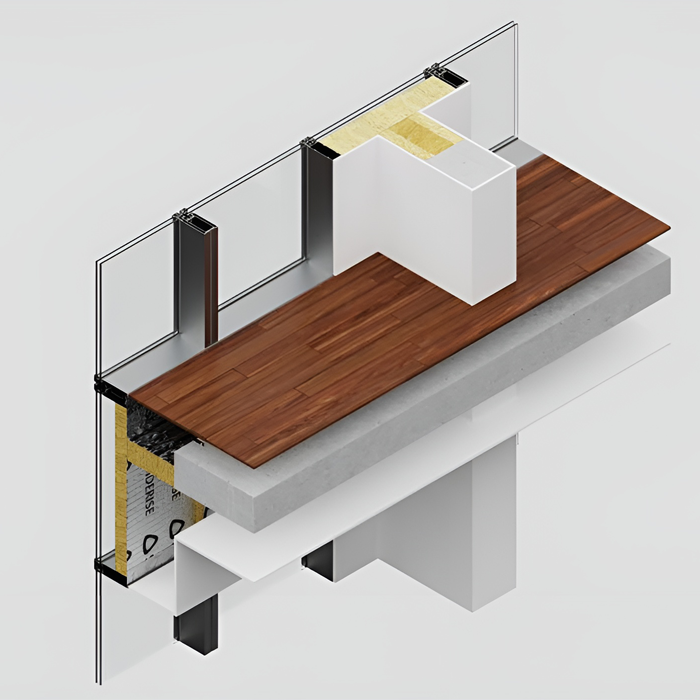

Due to its non-combustible core, this fantastic product meets stringent fire regulations and hugely increases the possibilities when it comes to creative building design.

As with all Alucobond products, Alucobond A2 allows for simple processing, is impact-resistant, break-proof, and weatherproof – and above all non-combustible.

Product Properties

| Panel Thickness | Standards | Unit | 3mm | 4mm |

| Thickness of Aluminium Layers | [mm] | 0.5 | ||

| Weight | [kg/m²] | 5.9 | 7.6 | |

| Technical properties | ||||

| Section modulus | DIN 53293 | [cm³/m] | 1.25 | 1.75 |

| Rigidity (Poisson's ratio µ = 0,3) | DIN 53293 | [kNcm²/m] | 1250 | 2400 |

| Alloy | EN 573-3 | EN AW 5005A (AIMg1) | ||

| Temper of Aluminium Layers | EN 515 | H22 / H42 | ||

| Modulus of Elasticity | EN 1999 1-1 | [N/mm²] | 70.000 | |

| Tensile Strength of Aluminium | EN 1999 1-1 | [N/mm²] | Rm ≥ 130 | |

| 0.2 % Proof Stress | EN 485-2 | [N/mm²] | Rp0,2 ≥ 90 | |

| Rp0,2 ≥ 90 | EN 485-2 | [%] | A50 ≥ 5 | |

| Linear Thermal Expansion | EN 1999 1-1 | 2.4 mm/m at 100ºC temperature difference | ||

| Core | ||||

| Mineral filled polymer | ||||

| Surface | Coal Coating | |||

| Lacquering | Fluorocarbon based (e.g. PVdF) | |||

| Gloss (Initial Value) | EN 13523-2 | [%] | 30-80 | |

| Pencil Hardness | EN 13523-4 | HB-F | ||

| Acoustical Properties | ||||

| Sound Absorption Factor αs | ISO 354 | 0.5 | ||

| Sound Transmission Rw | ASTM E90 | [dB] | STC: 30 | OITC: 24 |

| Loss Factor d | EN ISO 6721 | HB - F | ||

| Thermal Properties | ||||

| Thermal Resistance | ASTM C518 | [m²K/W] | 0.007 | 0.009 |

| Temperature Resistance | [°C] | -50 to +80 | ||

| Fire Classification | acc. to EN 13501-1: Class A2, s1, d0 | |||

Downloads